Founded in 1979, Labman Automation (United Kingdom, https://www.labmanautomation.com) produces world-leading customer laboratory automation and products.

Labman contacted TPL Vision for assistance as they needed a high brightness illumination for their Rapid Sample Reformatter, a system specially designed for the high throughput sub-sampling of large volumes of CoViD-19 test samples from capped vials into well plates for analysis. They needed a powerful, high brightness backlight, that could help them solve their illumination challenges.

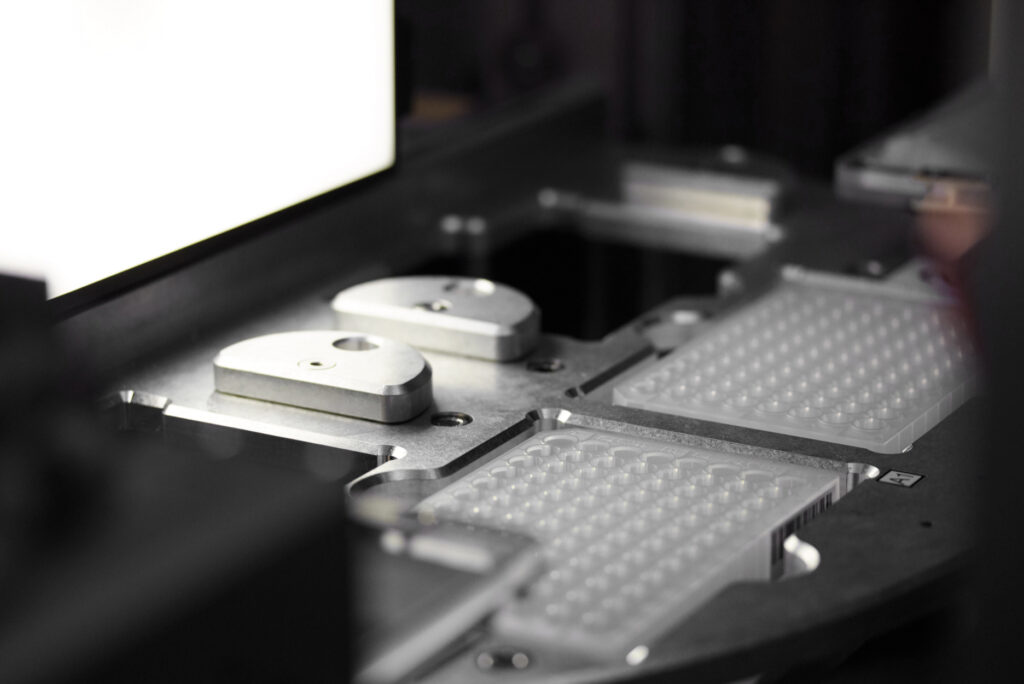

TPL Vision’s SBACK II backlight illuminating three pipette tips at a time to enable the verification of liquid levels.

Solution

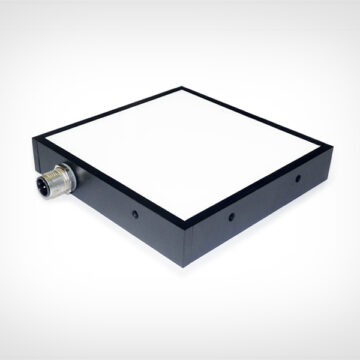

- SBACK II: High homogeneity in a small package

The SBACK II provides a consistently high homogeneity over the whole illumination surface, thus ensuring consistent imaging results are obtained, no matter where the samples are located. As a result of this high homogeneity, the three samples imaged at once had the same image quality and contrast across the entire field of view.

- Strobe and continuous working

The SBACK II can operate in strobe mode, which allows to better control the temperature of the LEDs, thus allowing a continuous 24/7 operation. Strobing also extends the product’s lifetime.

- A backlight with a small footprint

The selected backlight is only 20 mm thick with extremely narrow borders, making it very easy to integrate. It highlights the global shape of the tips of the vials, enabling the verification of liquid levels and any drips on the outside.

- Consultation and advice

TPL Vision’s machine vision engineers worked with Labman to fully understand the system’s setup and operation. All details of the application that could have an effect on the imaging results were considered prior to recommending the optimum illumination solution.

Challenges

- Being able to homogeneously illuminate the entire field of view

To ensure a quick inspection of thousands of vials per day, 3 pipette tips were inspected at the same time. It can be tricky to create homogeneity over the whole working area, especially if this working area is large. Labman had to ensure that the quality of illumination was sufficient to provide consistent results for a fast inspection system.

- The necessity to work in continuous operation, day and night

Due to the emergency character of the COVID-19 situation, a powerful, long lasting illumination was crucial to permit operating continuously.

- Lack of space

Labman required a very thin, yet powerful backlight. The space for illumination was limited; therefore, they were keen to find a solution that’s easy to integrate while still providing optimal brightness and contrast for inspecting the vials.

- No room for errors

High speed production lines are a challenge for many machine vision and robotics applications due to having to ensure that no feature of the part being inspected moves more than a single pixel of the camera’s field of view to avoid image blur.

The application needed a powerful backlight but had limited space for illumination.

Why should I strobe my products?

TPL Vision advises consumers to strobe our LED lights as often as possible, because doing so minimises the amount of heat produced by the product and lengthens the lifespan of the LED chip. Using LED illumination products in strobe mode whenever possible can help with extending product lifespan.

Results

The Rapid Sample Reformatter is now successfully inspecting at a speed where the human inspector cannot keep up. By automating this process they are now able to inspect up to 20,000 samples per day. The full process originally required 16 people to inspect; now, only 2 people are present to control the machine.

Further to this, Labman have begun improving the system such that 4 samples can be inspected at once, resulting in a higher throughput thanks to the uniform lighting provided by TPL Vision.