What is Polarisation?

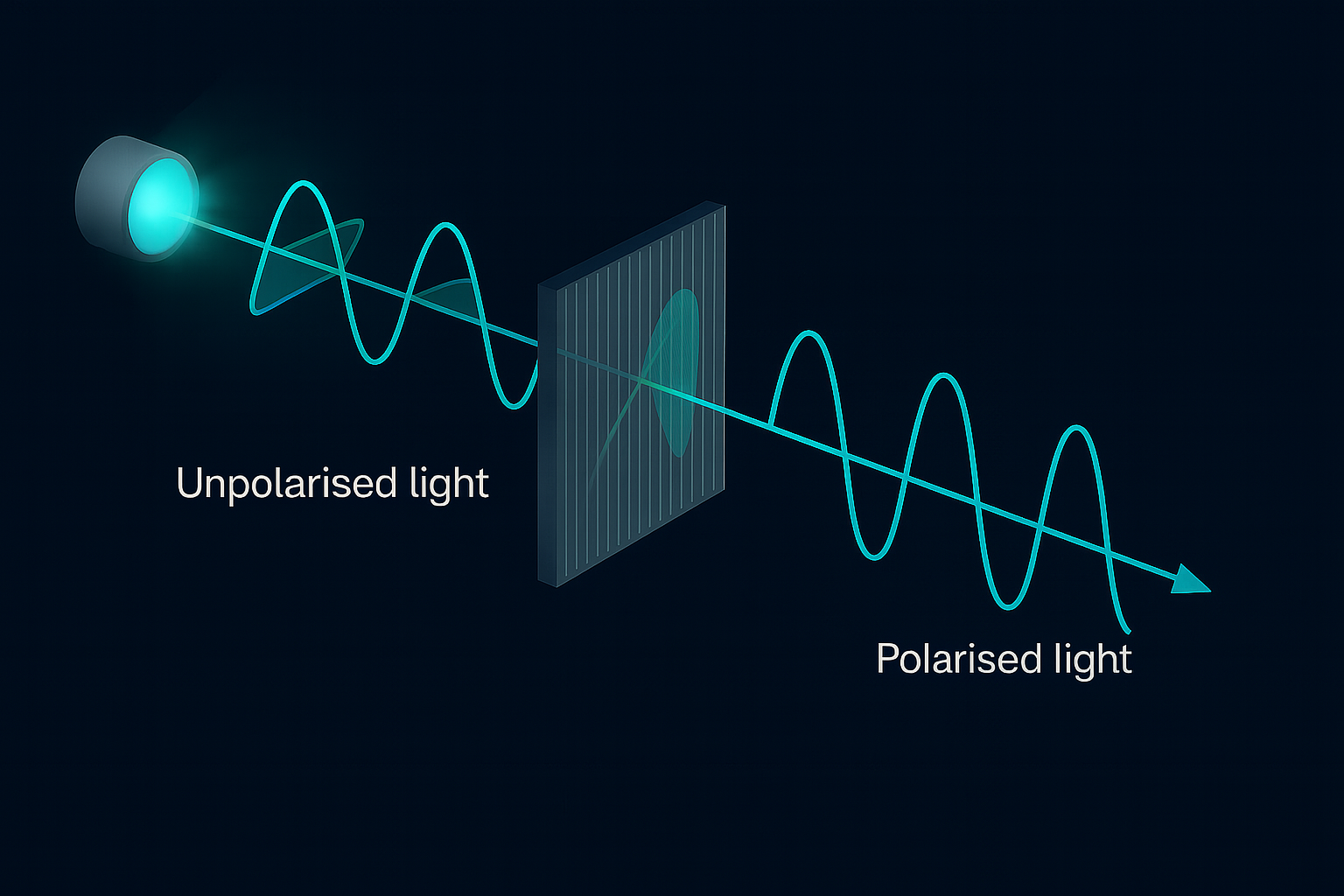

Polarisation is a lighting method we often hear about in machine vision applications. To understand polarisation, we must first consider light. Light is a type of wave, and when this moves it vibrates in many directions. When you add a polarising filter, this will block all but one wave by using aligned molecules that absorb unwanted vibrations. This creates polarised light. When two polarising filters are placed together, the amount of light that passes through depends on their angle. If they are aligned then light passes but if they are turned 90 degrees to each other, no light will get through. By rotating one filter, you can control the light intensity in a similar way to dimming.

In machine vision inspections, polarisation is an effective lighting method that improves image quality, enhances contrast, and reveals material properties that are not clearly visible with standard imaging techniques. With the help of polarisation, machine vision systems can tackle common challenges like glare and reflections to carry out the most effective inspections.

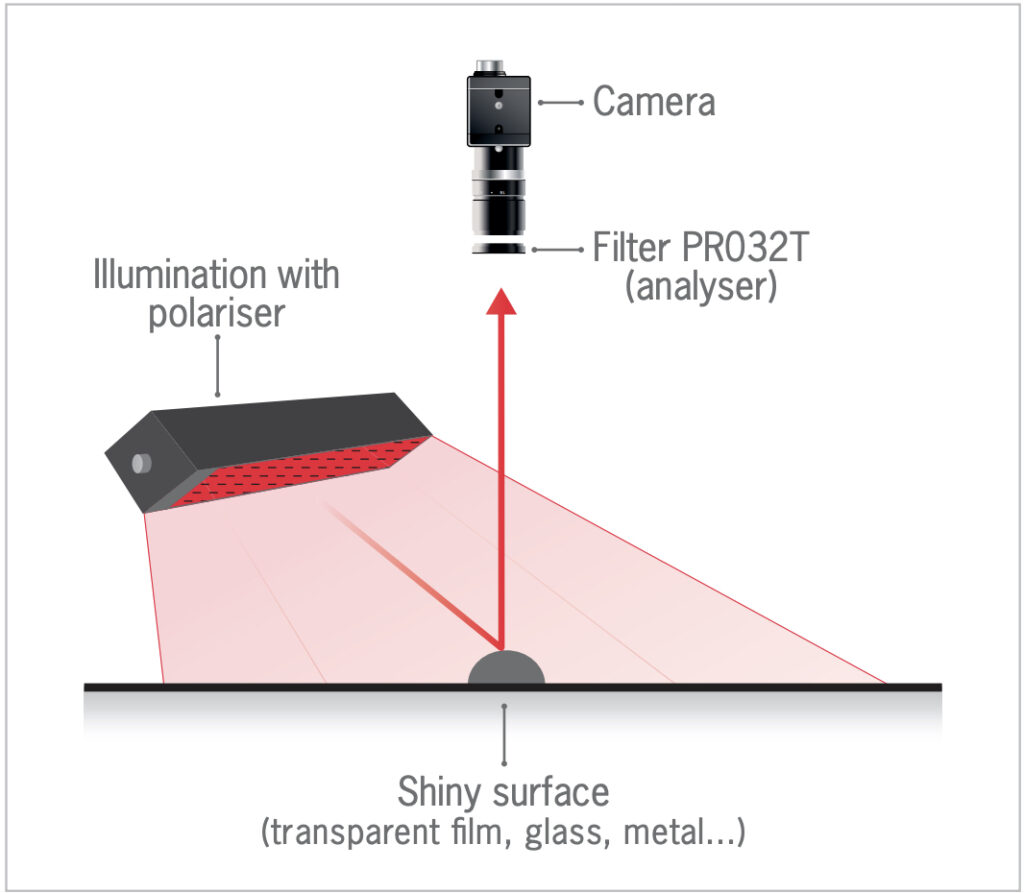

How it Works

Polarisers are used in machine vision to reveal textures and scratches on materials. With polarising filters, operators can control the way light waves vibrate to reduce glare and reflections on surfaces during inspections. This means only one kind of light vibration passes through while unwanted light is blocked out. As a result, the system captures clear images that highlight subtle features that the camera would usually miss.

Advantages

As a simple and cost-effective solution, polarisers are extremely useful for quality control, highlighting fine details, and reducing unwanted glare across a range of applications. They provide machine vision systems with an innovative method for extracting information from a scene that is invisible when using standard lighting methods.

By providing even more contrast and detail to industrial inspections, polarisers are significantly effective in a variety of industrial, scientific, and medical applications.

Challenges

- Reduction in Light Intensity – Polarisers block light that follows a different orientation. This will reduce the amount of light by about 50% and components not in the alignment are blocked out.

- Different Material Properties – Some materials, especially those that reflect or transmit light in a polarised manner, respond well whilst others don’t, so this limits their use in certain types of applications.

- Curved Surfaces – Since light reflects at many angles on curved objects, a single polariser setup may not reduce glare consistently across the surface.

Solutions

- Light Intensity – Use a brighter light source or increase camera exposure to counteract reduced brightness.

- Use with Materials – Test materials beforehand to find out how effective the polariser will be. Some applications will require both polarised and unpolarised lighting to capture different surface features. Adjusting lighting angles or using polarisation-sensitive cameras can improve results on less responsive materials.

- Curved Surfaces – Adjusting light angles or using advanced cameras that analyse polarisation in real time can improve performance on complex shapes.

TPL Vision Polarisers

TPL Vision offers a range of polarisation filters designed to reduce glare, eliminate reflections on shiny surfaces, and enhance image clarity. They’re especially useful when inspecting items packaged in reflective materials like transparent plastic bags.

Examples

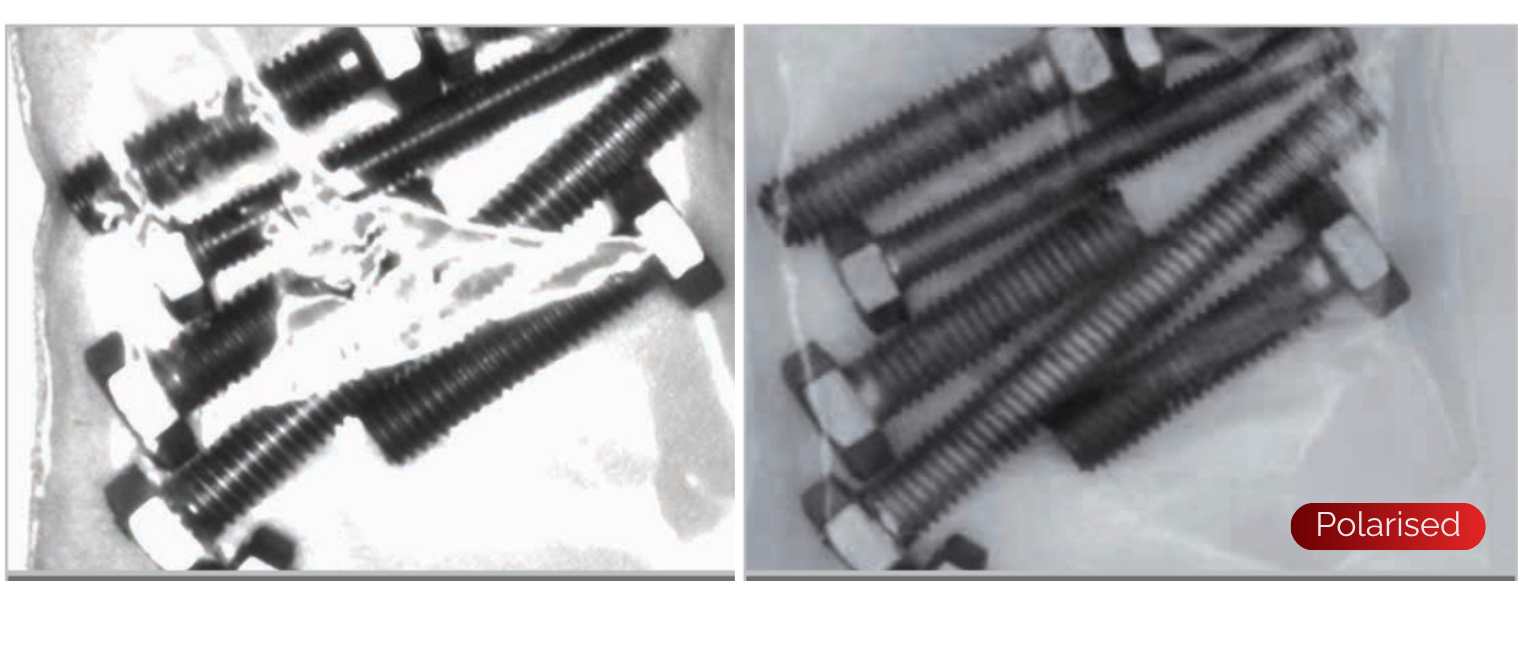

BAR LIGHT POLARISERS – These are available in a wide range of dimensions, from 125 mm to 1750 mm. They can be easily inserted into the enclosed transparent diffuser or supplied pre-integrated into our Angle Changers for bar lights. They reduce unwanted reflections, making bar lights even more adaptable across a larger selection of inspection tasks.

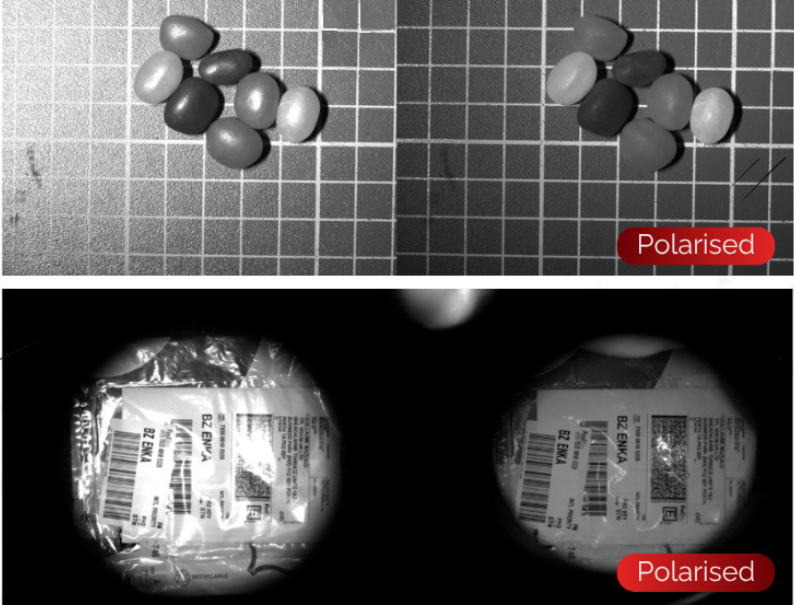

APPLICATION EXAMPLE – In automated systems inspecting packaged goods such as electronics, food, or medical supplies, bar light polarisers reduce reflections from plastic wrap. This allows cameras to clearly detect defects, labels, or missing components, even when the packaging is shiny or wrinkled.

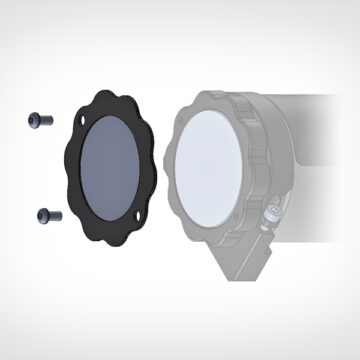

RING LIGHT POLARISERS – We also offer dedicated polarisers for our ring lights, ideal for compact spaces and high-contrast applications. They operate similarly to bar light polarisers and are perfect for highlighting details in compact setups. For best results and a longer filter life, we recommend using them in strobe mode.

APPLICATION EXAMPLE– In high-precision counting tasks like verifying the number of components, a ring light with a polariser ensures clear visibility by cutting glare from reflective surfaces. This setup helps maintain accurate counting and reliable quality control, even in tight spaces.

DISCOVER more about our polariser filters and compatible lighting options over on our website:

POLARISATION is a powerful yet simple technique that significantly enhances machine vision performance across a wide range of applications. By reducing glare, improving contrast, and revealing fine details, polarisers help inspection systems deliver more accurate, reliable results. With flexible options like bar and ring light polarisers from TPL Vision, it’s easy to tailor lighting setups for even the most reflective or complex inspection challenges.