Enhancing Machine Vision with Polarisers

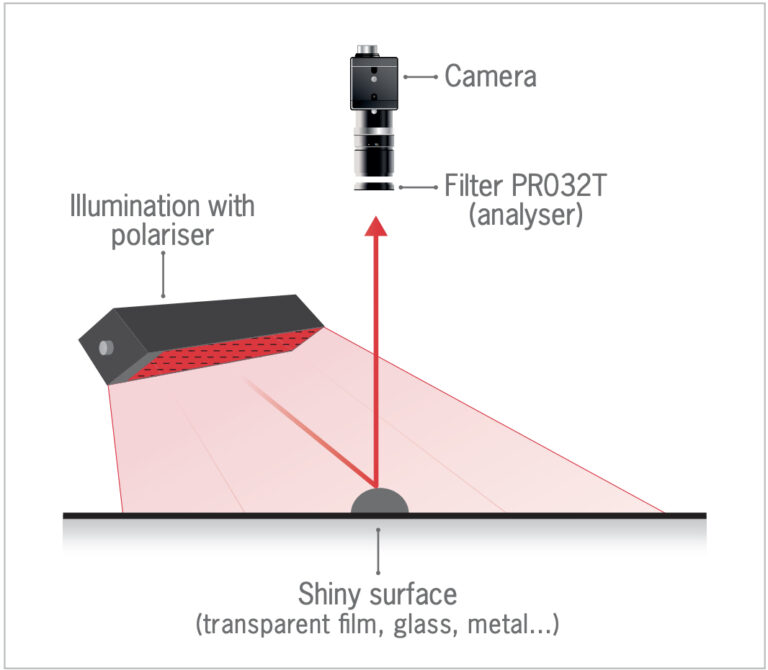

What is Polarisation? Polarisation is a lighting method we often hear about in machine vision applications. To understand polarisation, we must first consider light. Light

What is Polarisation? Polarisation is a lighting method we often hear about in machine vision applications. To understand polarisation, we must first consider light. Light

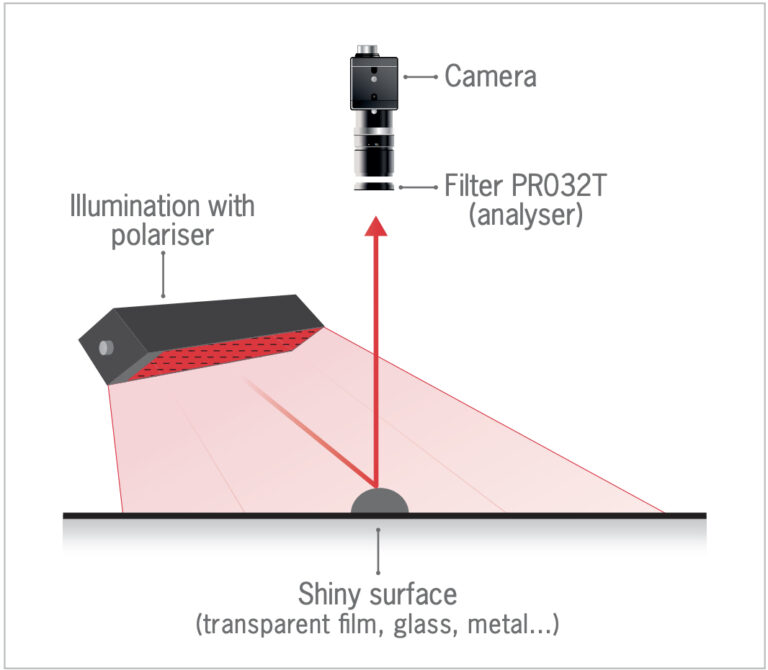

Tires are inspected from the top and the bottom simultaneously to ensure compliance, traceability and defect detection. The system checks for surface defects, tread pattern, DOT codes and branding elements, as well as the overall integrity of tires.

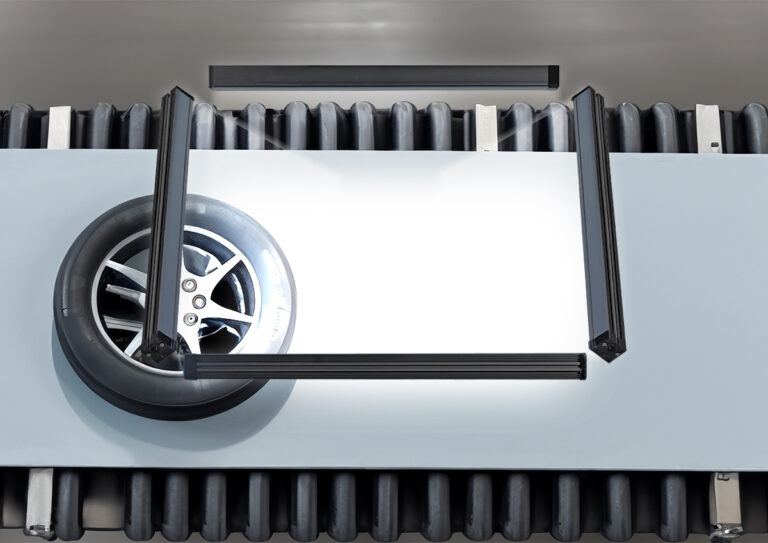

In this pick-and-place application, high-speed conveyor belts carry freshly baked cookies to be expertly packaged. The vision system uses high brightness IP69K-rated bar lights to accurately determine the cookies’ location and orientation.

During a crucial step in the automobile assembly process, a camera-based vision system is employed to verify the presence and positioning of components. Enhancing the camera’s capabilities, powerful diffuse bar lights are integrated onto a collaborative robot (cobot).

Inspecting sterilised surgical tools, this machine vision system features 25 cameras and a unique set of high-brightness bar lights to achieve a very high specification required for inspection the medical industry.

Learn how deep learning is transforming the automotive industry with this innovative vision solution for automated vehicle inspections.

Precision is key in robotics, and this robot-guided vision system updated with our powerful bar lights delivers just that. Discover how bar lights can improve accuracy in robotics by reducing the impact of ambient light.

The carpodX inspection system can examine the entire exterior of a vehicle from roof to underbody in just 3 seconds, increasing the productivity of the vehicle handling process and the inspection and survey procedures. Described as ‘the future of vehicle handover inspection’, the fully automated drive-through capture system takes up to 4000 HD photos during the visual inspection process.

ProSpection Solutions’ Foreign Material Detection and Removal Systems for washdown environments utilize TPL Vision’s IP69k-rated bar lights to detect contaminants in food products. With simultaneous top and bottom inspections, these systems ensure accurate and real-time detection of contaminants as small as 2mm2.

TPL Vision has worked with MV Center (Poland, https://www.mv-center.com) on a line scan application dedicated to inspecting TV components for one of the largest manufacturers in Poland.