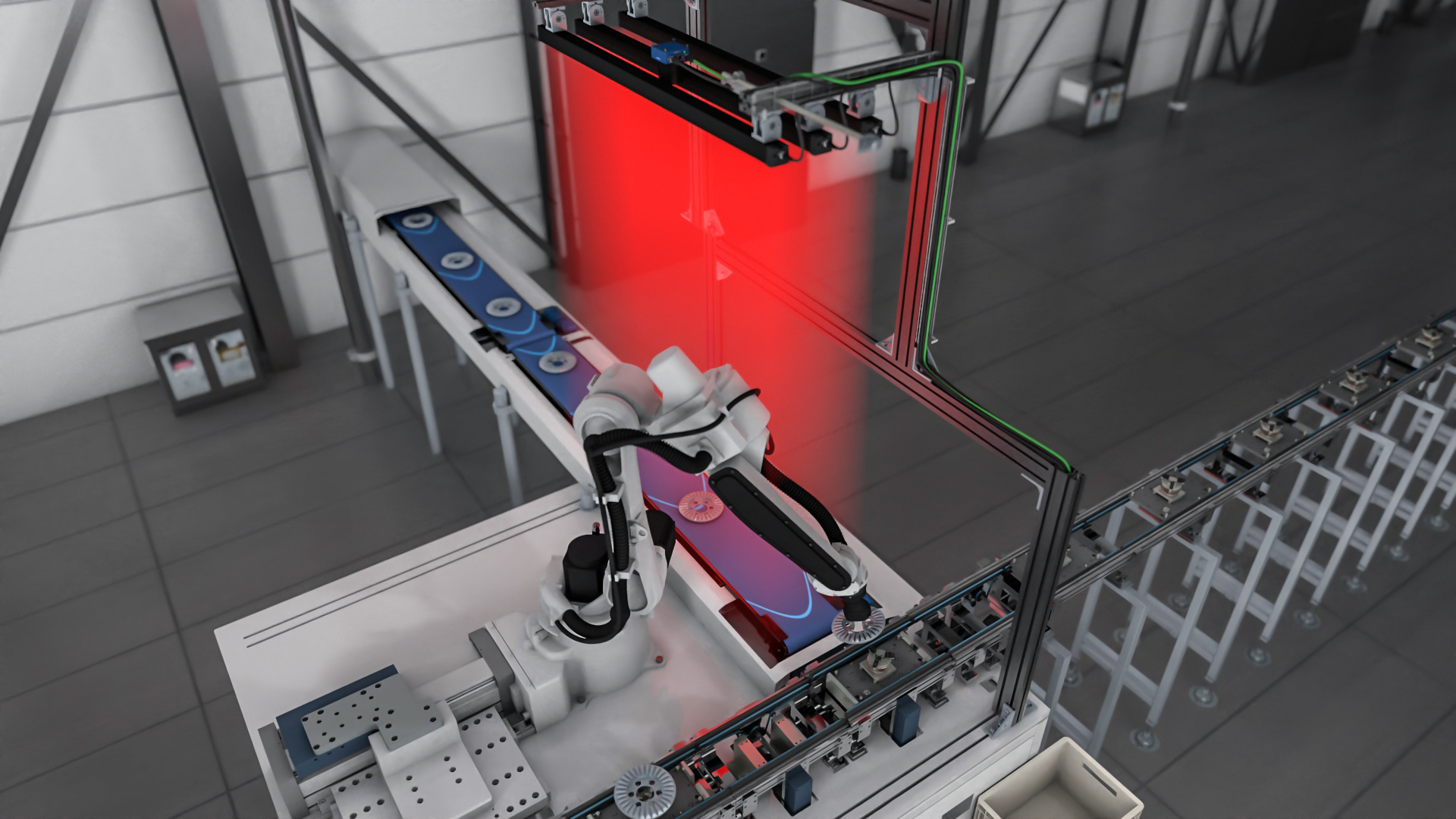

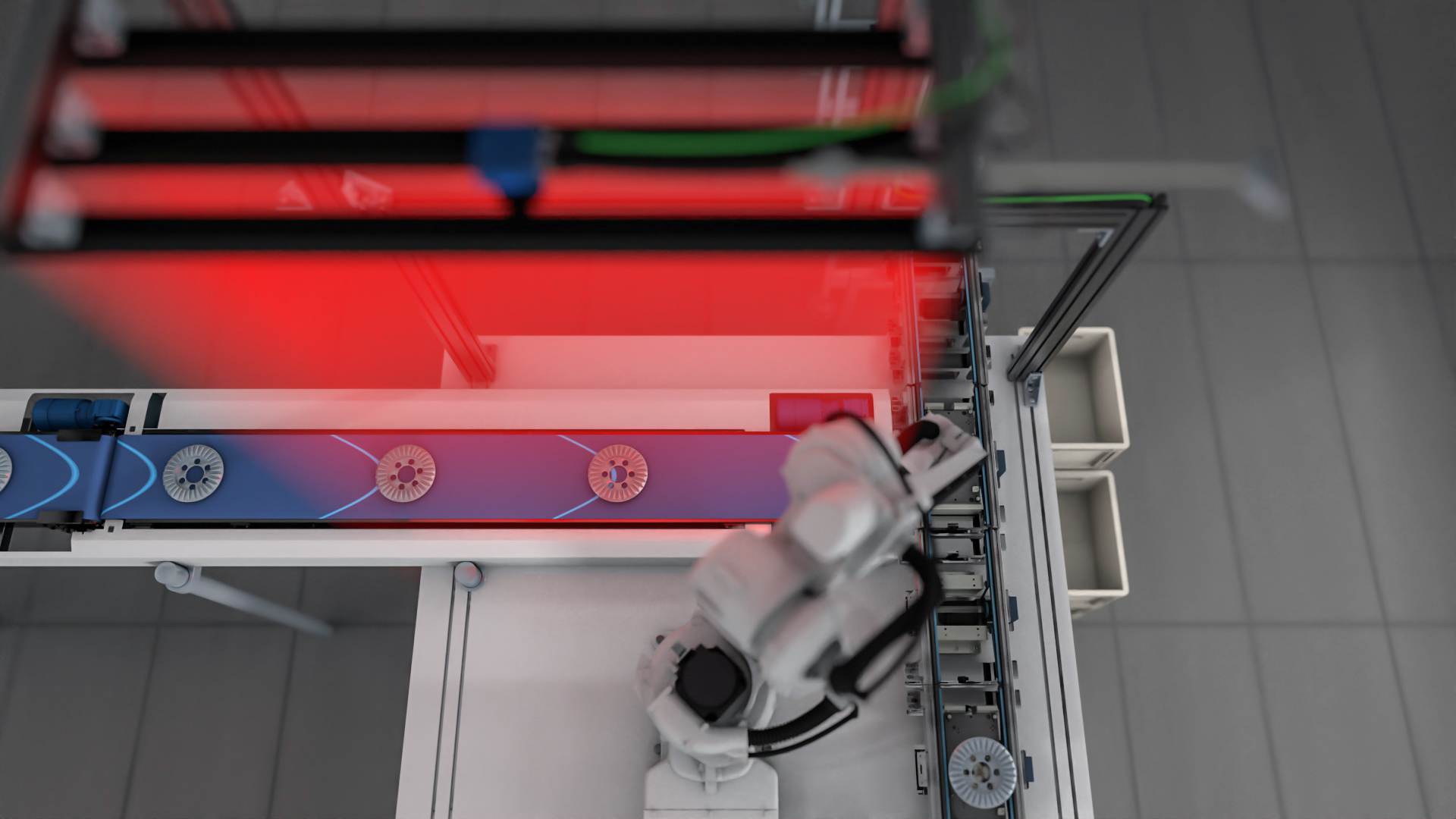

Robot arms are regularly used in gear manufacturing, particularly in pick and place automation tasks. To help optimise performance, reliable lighting is essential to ensure the robotic vision system can accurately detect parts for handling.

In this case, the robot arm had to pick up gears from the assembly line and place them in the next stage of production.

Uniform Illumination

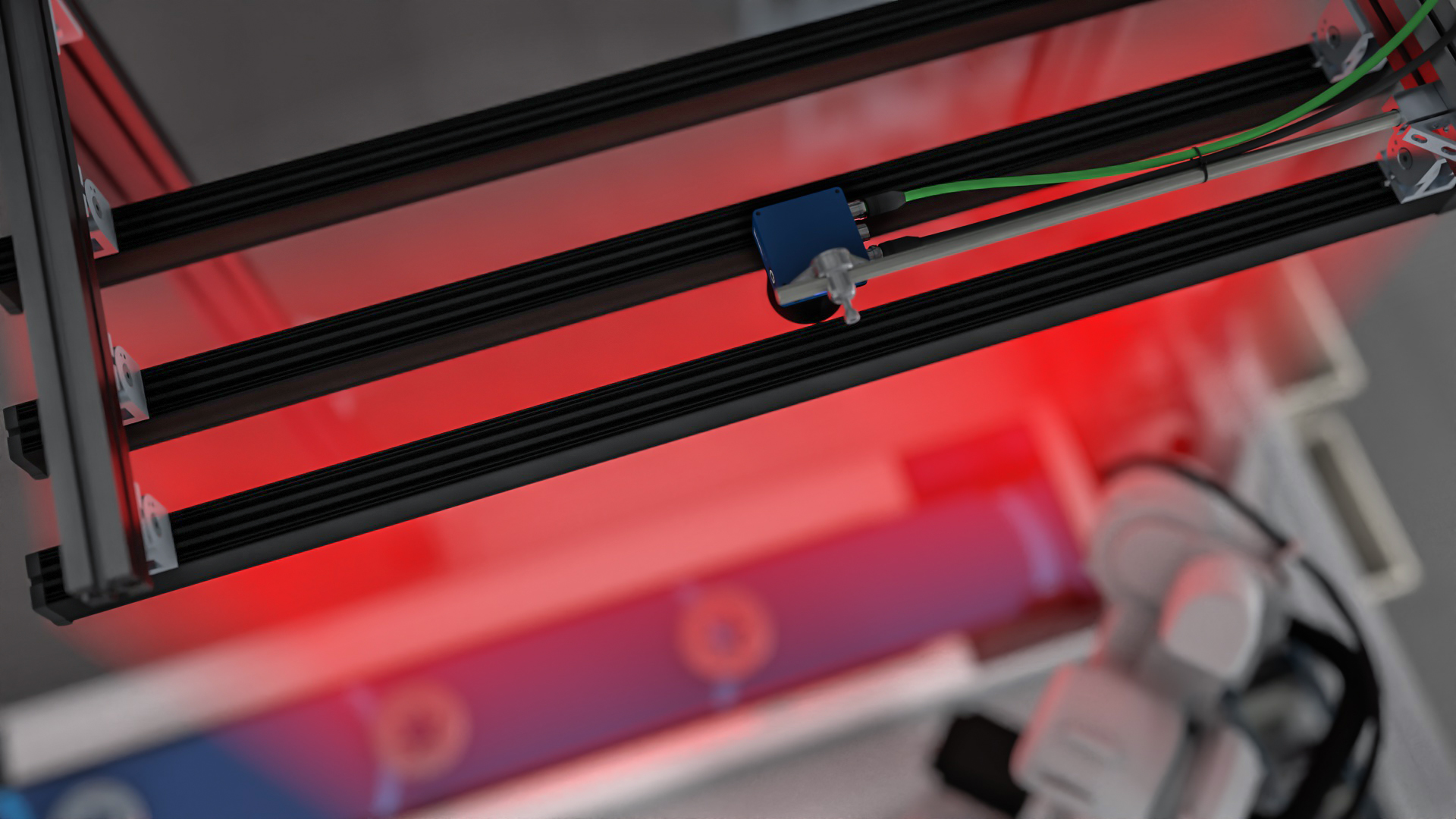

To achieve this, three of our Essential EBAR+ bar lights were used to produce uniform, homogeneous lighting. Mounted at a far working distance, the lights provided suitable space for the robot’s movement while casting an even beam to clearly highlight the gears. The length of the bar lights were wider than the vision system’s field of view, with overlapping coverage that ensured consistent illumination in both axes.

- The Essential EBAR+ proved to be particularly effective for this application thanks to its ability to deliver bright, uniform illumination over a wide area. Its linear design allowed for seamless coverage across the entire field of view, reducing shadows and reflections that could interfere with part detection.

- Additionally, the adjustable mounting options and varied beam angles made it easy to position the lights optimally for consistent lighting regardless of the robot arm’s movement. This combination of flexibility and consistent brightness provided reliable, high-precision gear handling.