Food manufacturers are responsible for ensuring that the best before or use-by date labels are correctly applied to every single product. Use-by dates are used to ensure the safety of products, while best before dates are used to ensure quality.

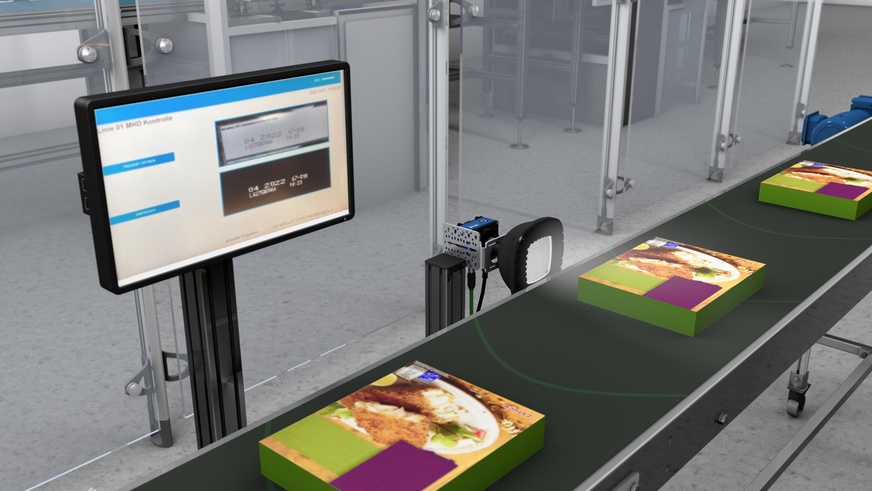

Without the correct application of labels, batches may be rejected, or they may face costly recalls if not identified in time. To eliminate the risk of this happening, this system uses OCR (Optical Character Recognition) for code presence verification and checking printing accuracy.

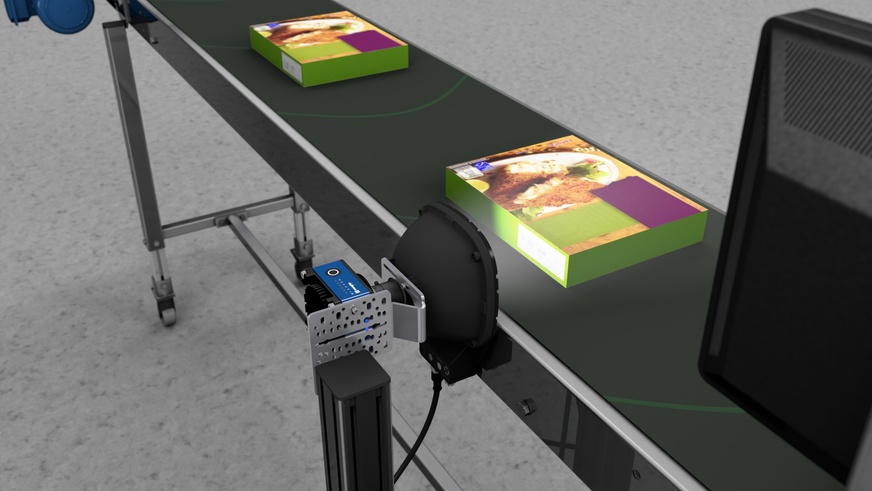

To examine the labels, a smart camera with a dome light at 90° is mounted next to the conveyor line, perpendicular to the packaging.

Challenges

- Code location: codes can be applied at different places on the packaging and backgrounds can change with product variations.

- Print quality: deformed or poorly printed codes must be identified with the highest accuracy. Shiny plastics can easily cause unwanted reflections.

- Fast speed of the conveyor: the conveyor belt is moving at a fast speed of more than one metre per second.

Solution

- Consistent illumination: ensures that codes are always read accurately regardless of the ambient lighting conditions and variations in product packaging.

- Uniform dome lighting: the addition of the dome light creates a uniform, shadowless illumination that’s perfect for the imaging of shiny or uneven surfaces.

- High brightness: the MR-Dome comes with embedded OverDrive for increased brightness in strobe mode that allows for shorter exposure times. Perfect for fast conveyors where products are in motion and motion blur can be problematic.

THE PERFECT ADAPTABLE PLATFORM FOR PRODUCTION NEEDS

The Modular Ringlight is a high brightness, flexible illumination platform designed for use across multiple applications. Used as a modular testing toolkit, it allows users to quickly identify the best illumination setup. Perfect for frequently changing production environments, as well as a platform for different applications requiring modified illumination methods that can be achieved with the Low Angle and Dome Light accessories.

Traceability in the Food and Beverages industry

Traceability refers to tracking the movement of products and ingredients through the supply chain, involving the monitoring and recording of key information at various stages, from production to distribution. Automated systems are increasingly employed to manage and monitor products, ensuring that they meet the required standards before reaching the customer. In the event of a recall, traceability systems allow companies to quickly pinpoint affected products, reducing the scope of the recall and minimizing potential harm to consumers.