Ultraviolet (UV) radiation is becoming increasingly common in machine vision applications, enabling detection capabilities beyond the range of human vision. With advancements in technology, UV vision systems are gaining traction, leading to increased demand for UV illumination and expanding the scope of machine vision applications.

What is UV Illumination?

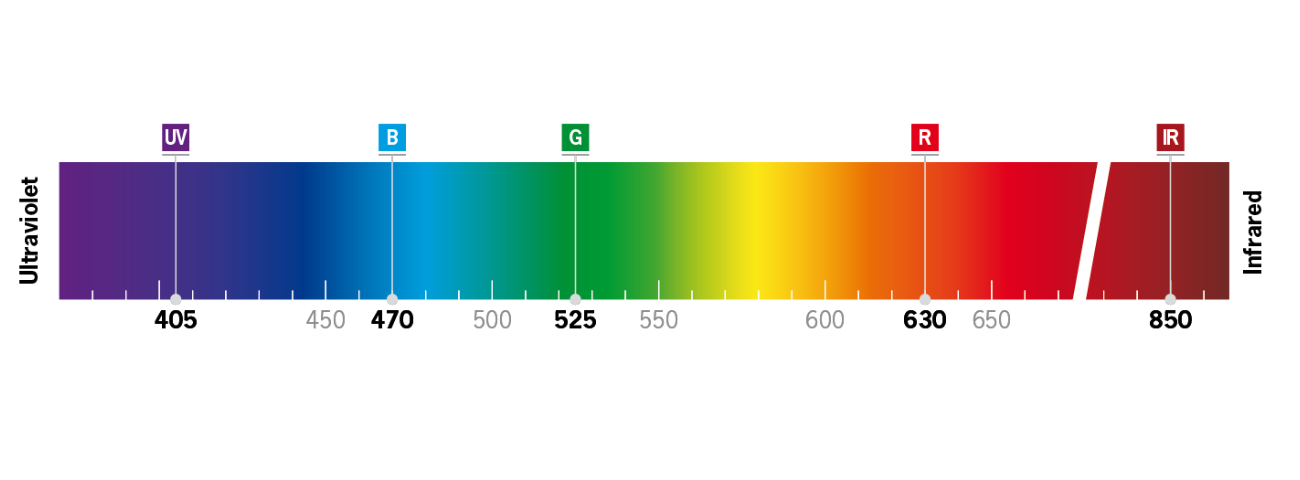

UV is a type of electromagnetic radiation with wavelengths that are shorter than visible light but longer than x-rays. It is invisible to the human eye and UV wavelengths range from 100 to 400 nanometres (nm). It is naturally emitted from the sun but can also be produced by artificial sources in industrial applications.

UV Illumination for Machine Vision

In the world of machine vision, UV illumination unlocks an entirely new sector of inspection power. Unlike standard LED lighting, UV light reveals what the naked eye can’t see. By creating fluorescence excitation in specialised materials, UV light highlights hidden features and illuminates microscopic contaminants with stunning clarity. This has elevated the industry, opening doors to advanced applications and expanding machine vision into wider markets.

UV Wavelength Bands

UV is divided into these wavelength ranges:

- UV-A (315 – *400 nm) – Most commonly used in machine vision. Used for fluorescence inspection, surface inspection, detecting invisible markings, adhesives, and inks. *Note: By definition, up to 400 nm but 405 nm is often used in machine vision.

- UV-B (280 – 315 nm) – Has deeper penetration and higher energy. This is less common in machine vision due to safety concerns, but useful for specific inspection tasks for specialised material analysis or defect detection.

- UV-C (100 – 280 nm) – A rarely used option due to hazards and low sensor compatibility. For machine vision, UV-C is mainly used in specialised applications like germ detection or biofilm analysis.

UV-A spectrum is the most widely used UV band in machine vision because it offers both high performance and safety. It’s UV wavelengths (315–400 nm) trigger fluorescence in many materials, showing hidden features and contaminants, while remaining safe for most equipment and easy integration.

Machine vision systems using UV-A illumination are valuable in a range of industries. Applications include inspecting pharmaceutical packaging for tampering, verifying security features on documents and currency, and detecting contaminants on surfaces.

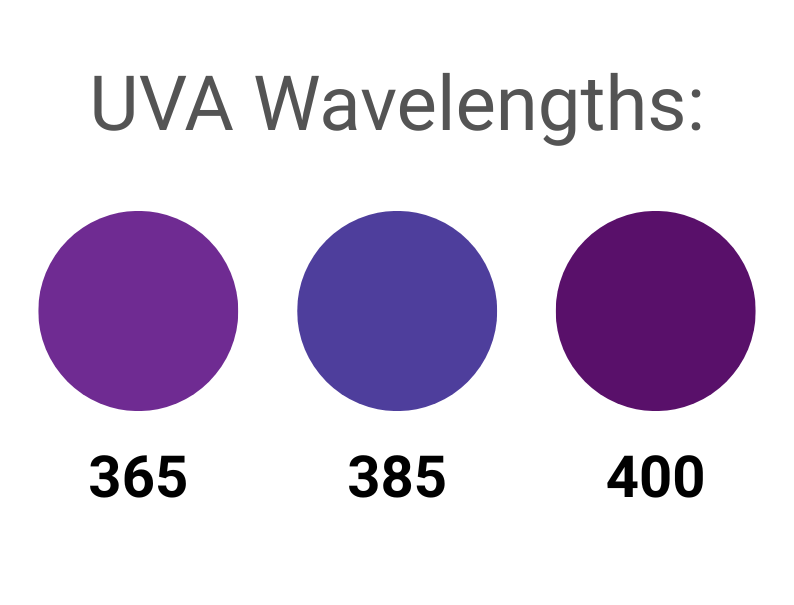

UV-A Wavelengths (315-400 nm)

365 nm

This wavelength is the industry standard for fluorescence imaging. It reacts with a wide range of substances like inks, glues, and dyes, making it ideal for applications that need high contrast. It’s particularly useful for detecting surface defects, invisible markings, and contaminants that can’t be seen under visible light.

Commonly used in applications:

- Pharmaceutical Packaging Inspection

- Adhesive verification

- Anti-counterfeit inspection

- Forensic-quality defect detection

- Cleanliness verification

375–385 nm

This range produces strong fluorescence in many materials. With broader LED availability and greater efficiency, this option is a practical choice for general-purpose UV inspections with enhanced durability and performance.

Commonly used in applications:

- Food and beverage inspection

- Automotive assembly

- Cosmetic packaging quality control

- Textile or fabric inspection

395 nm

Positioned near the edge of the visible violet spectrum, 395 nm doesn’t create as much fluorescence, but it is excellent for inspecting materials that reflect or absorb UV strongly. It’s commonly used in applications that need more reflectivity than fluorescence, like in surface texture analysis or detecting marks on dark materials.

Commonly used in applications:

- Surface inspection on dark materials

- Label presence verification

- Printed circuit board and component checking

- Packaging seal inspections

405 nm - Just Beyond the Visible Violet Spectrum

Positioned at the very edge of visible light, 405 nm serves as the transition point between UltraViolet and the visible spectrum. While it generates less fluorescence than shorter UV-A wavelengths (e.g 365 nm), it offers strong advantages in applications that rely on reflectivity and contrast rather than fluorescence.With high light output and wide availability, 405 nm is an excellent choice for machine vision systems that require bright, uniform illumination without overstimulating fluorescent materials. The EBAR + UV 405 offers a practical implementation of this wavelength, providing uniform illumination for machine vision inspections where contrast and reflectivity are critical.

405 nm is commonly used in UV vision applications:

• High-speed surface inspection

• Mark and code reading on reflective or dark materials

• Dimensional and alignment checks

• General-purpose machine vision where visible light may cause glare

Selecting the Correct UV Light Solution

Choosing between 365 nm, 375–385 nm, 395 nm, and even 405 nm depends on your application needs. It’s essential to consider the materials you’re inspecting and the visual effect you require. Use 365 nm for strong fluorescence and high contrast, 375–385 nm for a balance of performance and durability, 395 nm when reflectivity matters more than fluorescence, and 405 nm when you need bright, uniform illumination without overstimulating fluorescent materials. Matching the UV wavelength to your inspection goal ensures optimal imaging results and system efficiency.

As UV vision technology continues to advance, its role in machine vision is becoming more impactful than ever. By leveraging the unique capabilities of UV illumination, industries can achieve greater inspection accuracy, uncover hidden defects, and maintain higher quality standards across a wide range of applications. As machine vision systems evolve, UV lighting remains a powerful tool for pushing the boundaries of what’s visible—and what’s possible.

Related products

-

Essential ELINE Collimated

- Modular line scan light

- Sizes up to 2500mm

- Passive Cooling

-

Zoom Z-SPOT

- High-power spot light

- Variable zoom lens

- M30 Housing with IP67 rating

-

Essential EBAR+ UV 405

- Powerful UV405 bar light

- Lens options for different FoV

- Sizes up to 1250mm

-

Fluorescence Imaging Solution

- Intense Fluorescence dome light

- Multi-UV + White

- Integrated BP filter