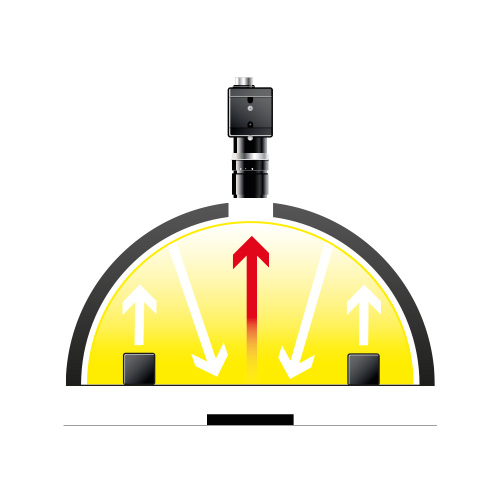

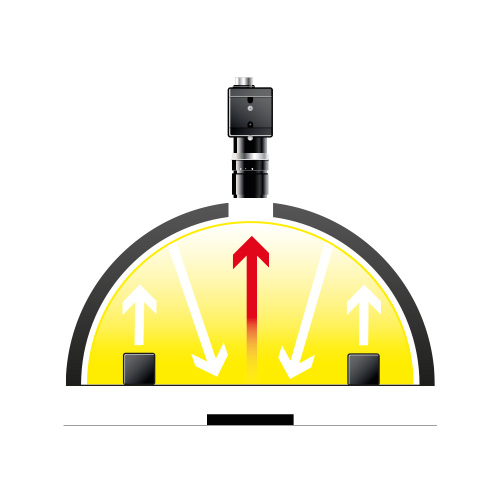

TPL Vision’s Fluorescence Imaging Solution* (FIS) is a flexible multi-wavelength UV dome light suitable for authentication, traceability and fluorescence inspection applications. Due to its unique design that allows users to test and select multiple UV wavelengths (UV365, UV395 & UV405), the FIS is suitable for the inspection of bank notes and excise stamps, as well as inspecting various levels of UV security and brand protection features used on pharmaceutical products, electronics and luxury goods, including perfumes and aftershaves, tobacco and alcohol products, and designer-branded goods.

Compatible with any visible spectrum camera, the FIS is an all-in-one UV solution that also maximises the safety of operators by blocking direct UV radiation through the dome and the integrated filter.

*Patent pending

The Vision Systems Design Innovators Awards program recognises the most innovative products and services in the vision and image processing industry. The Fluorescence Imaging Solution won a Bronze award in 2023.

To view all the technical information, please click on the tabs below.

UV (ultraviolet) rays are electromagnetic radiations situated between 280 and 400 nm. Although invisible for the human eye, these can be observed by fluorescence imaging. When submitted to UV wavelengths, fluorescent substances absorb and re-emit UV light as visible, longer wavelength radiation, typically blue (470 nm) or green (525nm). This can be inspected by a camera through the use of filters to block out any unwanted UV wavelengths.

Common ultraviolet light uses include medical and industrial processes used for disinfection and hygiene control, as well as commercial applications detecting security inks and fluorescent anti-counterfeiting packaging features. UV-fluorescent security markings are used to fight counterfeiting in the form of 2D codes, barcodes, alpha numeric codes, images and graphics, safeguarding brand authenticity and supporting supply chain tracking. Depending on the type of ink used, these features can become fluorescent at a wide range of UV wavelengths, but more specialised types of inks will only react to a narrow band of wavelengths. Traceability logos and codes come with the ability of embedding various types of information (batch numbers, inspection results, etc.) without affecting the design of the product packaging.

UV inks are often used as enhanced security features for identity documents such as cards and passports, as well as for excise stamps. These usually combine overt (visible to the naked eye) and covert (only visible using a tool) features. Covert features such as UV-fluorescent text or symbols make it harder to create counterfeits but are still easily detectable for verification purposes.

The Vision Systems Design Innovators Awards program recognises the most innovative products and services in the vision and image processing industry. The Fluorescence Imaging Solution won a Bronze award in 2023.

To view all the technical information, please click on the tabs below.

UV (ultraviolet) rays are electromagnetic radiations situated between 280 and 400 nm. Although invisible for the human eye, these can be observed by fluorescence imaging. When submitted to UV wavelengths, fluorescent substances absorb and re-emit UV light as visible, longer wavelength radiation, typically blue (470 nm) or green (525nm). This can be inspected by a camera through the use of filters to block out any unwanted UV wavelengths.

Common ultraviolet light uses include medical and industrial processes used for disinfection and hygiene control, as well as commercial applications detecting security inks and fluorescent anti-counterfeiting packaging features. UV-fluorescent security markings are used to fight counterfeiting in the form of 2D codes, barcodes, alpha numeric codes, images and graphics, safeguarding brand authenticity and supporting supply chain tracking. Depending on the type of ink used, these features can become fluorescent at a wide range of UV wavelengths, but more specialised types of inks will only react to a narrow band of wavelengths. Traceability logos and codes come with the ability of embedding various types of information (batch numbers, inspection results, etc.) without affecting the design of the product packaging.

UV inks are often used as enhanced security features for identity documents such as cards and passports, as well as for excise stamps. These usually combine overt (visible to the naked eye) and covert (only visible using a tool) features. Covert features such as UV-fluorescent text or symbols make it harder to create counterfeits but are still easily detectable for verification purposes.