This pharmaceutical pill inspection application uses the Black & Light (Bn’L) illumination as part of the vision system to enhance the manufacturing process. The dual-feature inspection ensures comprehensive quality assurance by addressing both physical characteristics (shape and size of the tablets) and the presence of necessary imprint codes (batch/lot number, expiration/manufacturing date, branding or generic identification).

The simultaneous inspection of tablet shape and imprints optimises the production workflow, providing a streamlined and efficient quality control process for the manufacturer.

This pharmaceutical pill inspection application uses the Black & Light (Bn’L) illumination as part of the vision system to enhance the manufacturing process. The dual-feature inspection ensures comprehensive quality assurance by addressing both physical characteristics (shape and size of the tablets) and the presence of necessary imprint codes (batch/lot number, expiration/manufacturing date, branding or generic identification).

The simultaneous inspection of tablet shape and imprints optimises the production workflow, providing a streamlined and efficient quality control process for the manufacturer.

Challenges

- Precision is key: for regulatory compliance, the pharmaceutical industry demands precise quality control. Achieving homogeneous lighting is essential for the assessment of tablets across the field of view.

- Both sides and the entire surface of the tablets must be inspected, without any blind spots.

- Any breakage, edge or surface erosion, or issues with the coating of the tablets must be identified. Occasionally the coating material can create an uneven surface and fill the logo/text/breakline on the pill, making them unreadable.

- The glossy coating of the pills can cause reflections and glare under intense illumination. Insufficient illumination may lead to misreads or failures to extract critical information, risking non-compliance.

Solution

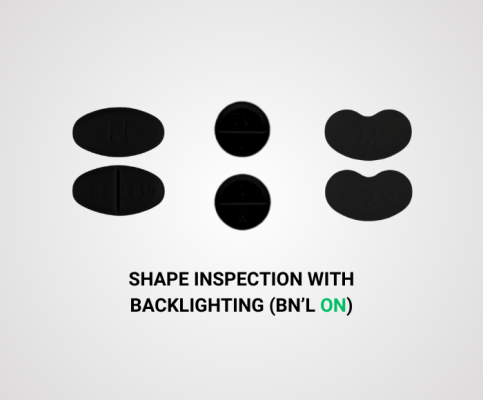

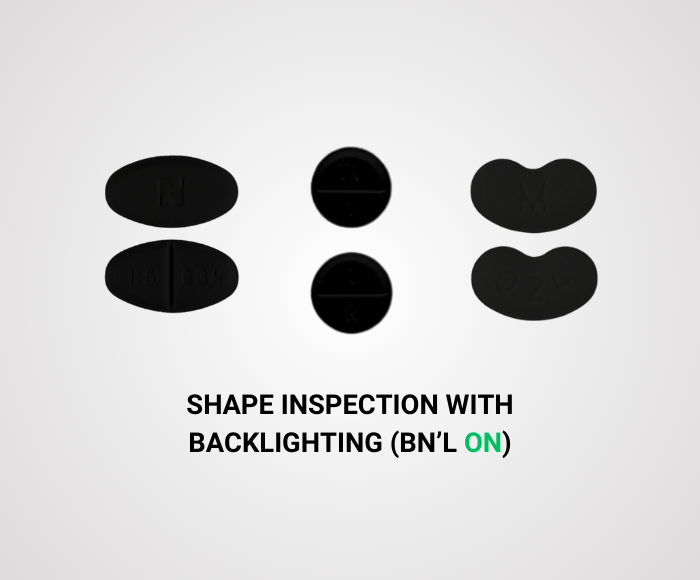

- Upon initiation, the uniform illumination of the Bn’L is activated to work as a high-intensity backlight for inspecting the shape and size of the pills. This enables high contrast for the system to precisely analyse each pill’s integrity and measure their dimensions. Any nonconformities due to manufacturing errors can be identified and removed safely.

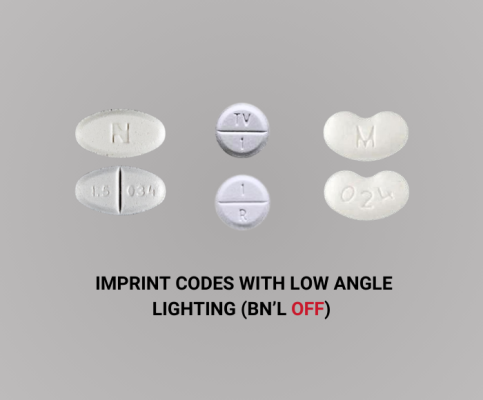

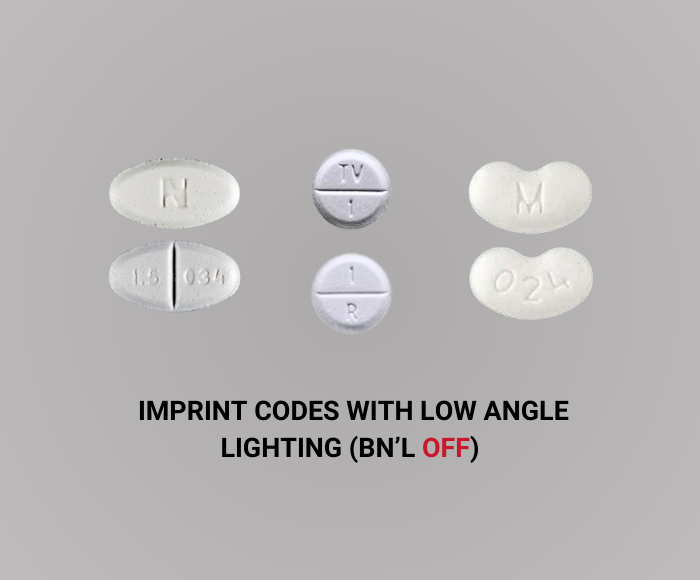

- To inspect the imprints and the presence of breaklines, the Bn’L switches off and acts as a dark background as the pills are illuminated using low angle lighting. This low-reflection matte background helps to reduce unwanted hot spots and absorb disturbing incident light.

- The optimal lighting conditions allow accurate readings and reliable extraction of crucial information. The flexibility of switching between backlighting and low angle lighting allows the system to carry out two inspections at the same workstation.