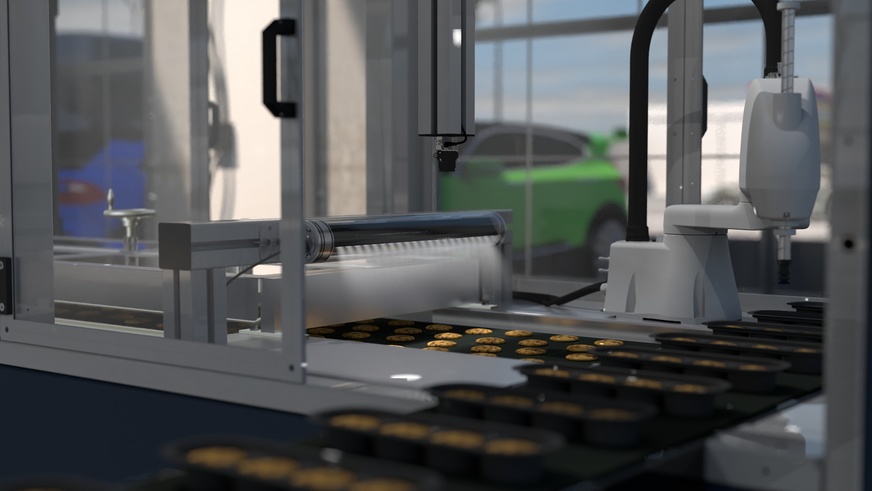

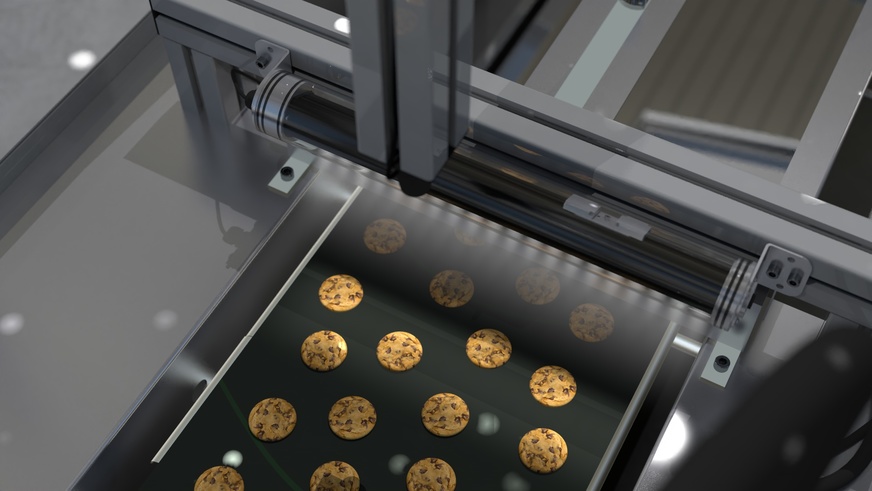

Similar to how many products in the food and beverages industry are packed, in this application, the freshly baked cookies are transported to the next stage on a fast-moving conveyor belt. Here, a robot handles the biscuits and places the correct amount in the packaging. It is vital that the vision system determines the exact location of the cookies, as well as their orientation, in order to ensure their correct placement.

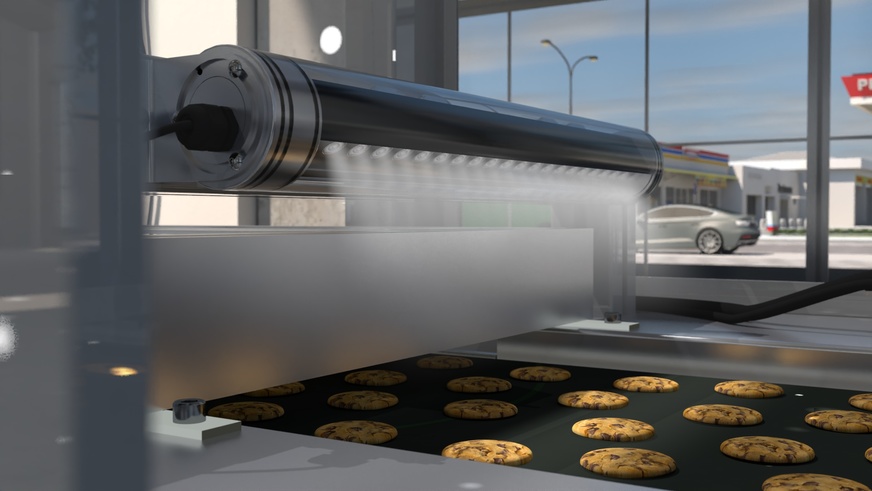

A line scan camera supported by the powerful illumination of a bar light are installed above the conveyor. With its stainless steel 316L housing, the bar light is a perfect addition to this environment due to its intense illumination output and ability to withstand high-pressure washdown and strong chemicals. The chosen bar light helps to create strong contrast and robust images for effective handling of products.

Challenges

- High-Speed Movement: The fast moving goods needed a lot of brightness to counteract motion blur.

- Contrast and Orientation: Low contrast between the conveyor and the biscuits posed a challenge. High contrast was also needed to help the system determine the orientation of the cookies.

- Harsh Environment: The vision system had to withstand strong chemical cleaning without degradation.

Solution

- High-Intensity Illumination: The chosen bar light’s intense illumination output provides sufficient light to overcome motion blur, ensuring clear and sharp images of the cookies in motion. Many machine vision systems used in the food industry log inspection data, which is invaluable for documentation and process improvement.

- Contrast Enhancement: The selected bar light creates strong contrast, enabling the vision system to distinguish cookies from the conveyor background with precision. With clear images of the cookies’ location and orientation, the system can ensure their precise placement in packaging.

- Robust Housing: The stainless steel 316L housing of the bar light ensures durability and resilience in harsh washdown and chemical environments, maintaining consistent illumination performance over time.

Did you know?

In the world of industrial protection ratings, the "K" in IP69K stands for "Kraftstrahl" in German, which can be translated as "powerful jet" in English. When you encounter the IP69K rating, you're not just looking at a robust product. You're witnessing the triumph of engineering over some seriously intense challenges, making these products the superheroes of durability in manufacturing settings.