From Automation to Deep Learning: Artificial Intelligence and The Future of Manufacturing

Leveraging the Strengths of AI and traditional Machine Vision

Leveraging the Strengths of AI and traditional Machine Vision

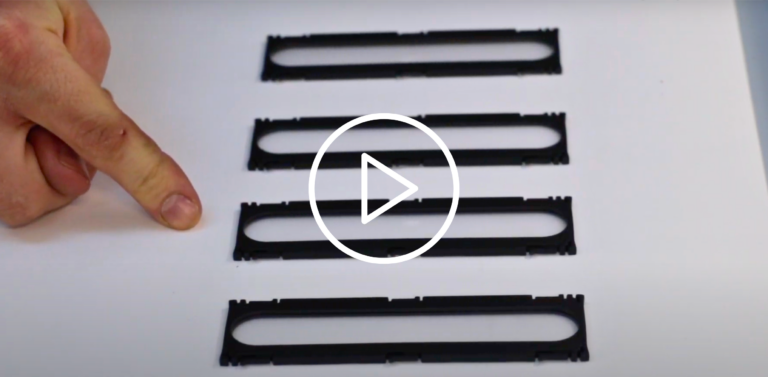

Learn what makes the Modular EBAR and Angle Changers so versatile in this video.

Video tutorial showing what you need to set up the M-EBAR for strobe and continuous working.

Find out how Angle Changers work and how you can benefit from their added flexibility.

Video tutorial: learn how to create TPL Vision’s patented Curve Effect.

The Modular Bar is designed with exceptional lighting homogeneity, and along with the Angle Changers, it is possible to illuminate FoVs of all sizes.

The dome effect is one of the best methods to illuminate shiny parts evenly.

The Modular Bar, when combined with the Angle Changers, gives the user both excellent uniformity and flexibility to operate in many configurations.

The Modular Bar comes with OverDrive integrated, which means the light is 4 times more intense when strobed for the first 30ms of the trigger signal.

The Modular Bar, along with the Angle Changers, is an excellent tool for linescan applications that are not at the extreme of high-end line scan applications.

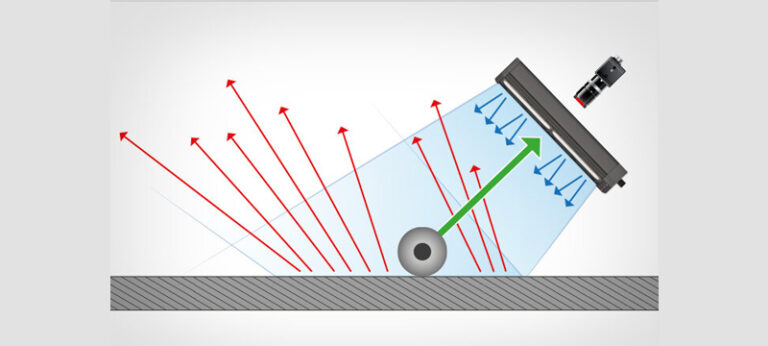

Using this method, it is possible to highlight features on shiny components.

To illuminate shiny parts from a distance, position both the camera and the light at an angle to the part that needs to be illuminated.

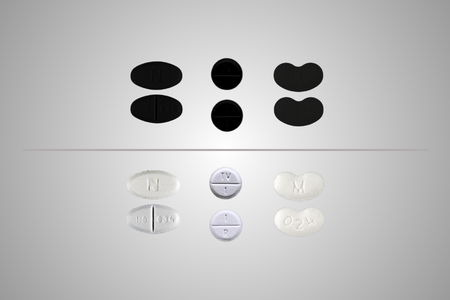

This dual-feature inspection streamlines quality control using the Black&Light (Bn’L). The system is able to simultaneously assessing shape, size, and imprint codes of the tablets.

Food manufacturers are responsible for ensuring that the best before or use-by date labels are correctly applied to all products. In this system, a dome light provides homogeneous illumination for label detection.

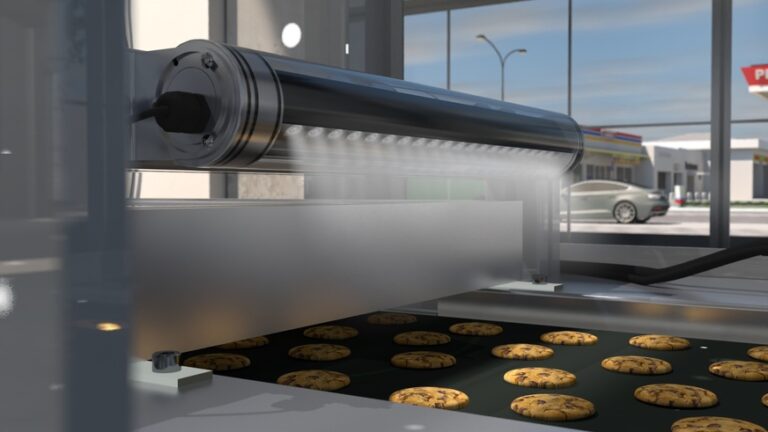

In this pick-and-place application, high-speed conveyor belts carry freshly baked cookies to be expertly packaged. The vision system uses high brightness IP69K-rated bar lights to accurately determine the cookies’ location and orientation.